If you are new to the thermal spray industry or recently started thinking about using thermal spray to treat your industrial parts, you should be aware of an important coating option.

Plasma spray coating is a type of thermal spray that uses heat as its primary source to create an extremely durable coating.

This type of spray coating produces a flame that can reach up to 27,000 degrees Fahrenheit, which makes this coating ideal to treat industrial parts such as metal that have a very high melting point.

How Does the Plasma Spray Coating Process Work?

There are several elements that create the high-temperature flame to directly treat an industrial part:

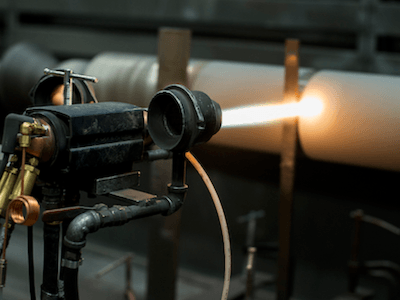

- A plasma spray gun acts as the source of the flame

- Plasma gas is fed into the spray gun as the heating source

- Plasma is created through an electric charge

- A powder coating is fed externally through a powder supply

- Plasma exits through a special anode nozzle to interact with the powder

- An extremely-hot flame is produced through the plasma spray gun to coat the part

What Are the Benefits of Using Plasma Spray Coating?

Plasma spray coating is essential for treating industrial parts that are used in high-dollar equipment exposed to extreme conditions, heavy use, or continual impact.

The parts are refined through fire to extend the life and durability of equipment. When placed back into service, the coated parts create these benefits:

- Thermal insulation

- Corrosion protection

- Wear prevention

- Oxidation resistance

Find Out More About Plasma Spray Coating

Plasma spray coating is one of many types of thermal sprays available in the industry. We recommend that you find out more about these types of coatings as you research the appropriate use for your industry or specific use.

If you have specific questions about plasma spray coatings or the overall thermal spray process, please contact us. We look forward to hearing from you.