Finishing Treatments: Phosphatizing

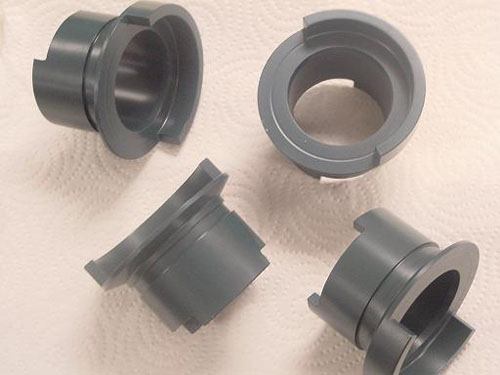

Superior Shot Peening & Coatings offers a phosphatizing finishing treatment to prepare metal or steel pieces for painting or coating, helping prevent corrosion.

Phosphatizing differs from traditional painting or coating because the surface of the metal is chemically changed to a new substance. This is important because the new coating will not chip or scratch, ensuring that the base material is not vulnerable to corrosion and wear.