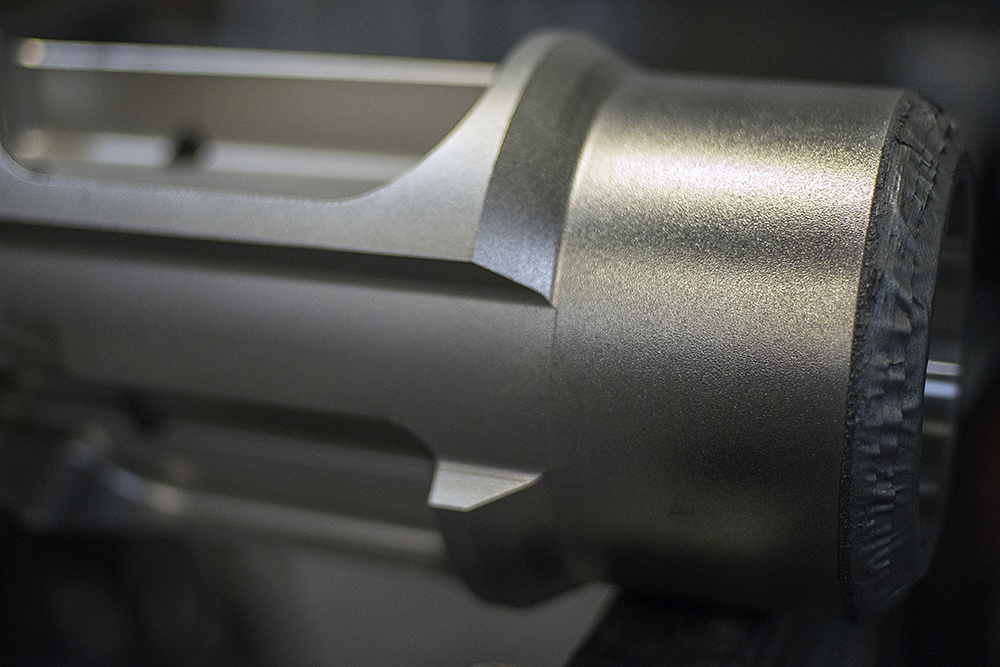

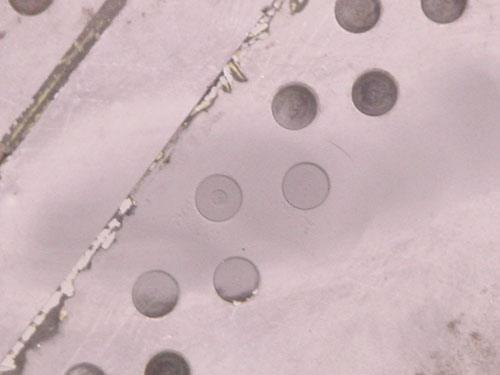

Finishing Treatments: Abrasive Blasting & Deburring

Superior Shot Peening & Coatings offers an abrasive blasting and deburring finishing treatment to clean metal. We use abrasives to scrape corrosion, burrs, flash, and other undesired particles from the metal, leaving the metal ready for further protective coatings and pre-treatments.

Abrasive blasting is used primarily in the following cleaning processes: Corrosion Removal, Deburring, Deflashing, Paint Removal, and Pipe Cleaning inside and out.