Over the past 30 years, Superior Shot Peening & Coatings (SSPC) has taken great pride in listening to our customers and offering new services to address emerging needs for the Houston area and worldwide.

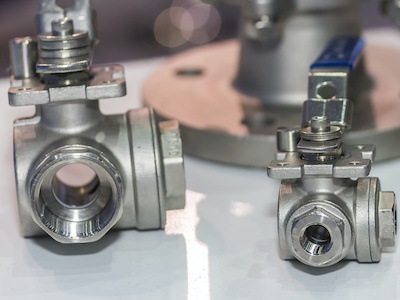

That’s why we are introducing a new Metal Seated Ball Valve coating service to improve the integrity of metal seated ball valves that are used in industries such as oil & gas, energy, manufacturing, aerospace, and other demanding industries.

This coating service is designed to support functionality of seated ball valves and ensure the durability and longevity of the part to withstand difficult conditions in harsh industrial settings.

We are utilizing the High-Velocity Oxygen Fuel (HVOF) thermal spray process to create a high-density, extremely wear-resistant coating on the metal seated ball valve.

Why Use A Ball Valve Coating Service?

The primary challenge with a metal seated ball valve is the metal-to-metal configuration. Because the metal ball is rubbing against the metal seat, this can easily create the undesired effect of galling.

A ball valve coating protects the integrity of the part in a metal-against-metal environment. This way, the part does not lose functionality in difficult conditions, during extreme weather, when there is heavy friction, or during prolonged use.

In addition to preventing galling, the protective coating increases wear resistance of the ball valve, protects against corrosion and the effects of harsh conditions, and improves performance of the equipment that uses the metal seated ball valve.

The Benefits of Using a Ball Valve Coating Service

Companies in oil and gas, energy, manufacturing, and other industries need solutions to keep equipment running and operable. To prevent costly downtime, key parts need to be coated to ensure longevity.

Ball valve coatings are the ideal choice to extend the life of a metal seated ball valve. This way, the part continues to provide value according to your production schedule without causing delays in production.

Another benefit of using this protective coating is avoiding the need for a costly replacement of the part.

Instead of ordering, waiting, and installing a new part, the ball valve coating can restore the part to its original condition at a fraction of the cost and in a much more timely manner. This prevents costly downtime in the field without sacrificing performance or quality of the part.

Contact SSPC For Ball Valve Coating Service

We are looking forward to serving the needs of customers in demanding industries that require exceptional durability and longevity of metal seated ball valves. Consider our Metal Seated Ball Valve coating service to restore these critical parts for extended use in your equipment.

Contact us today to schedule our new service for your next job.