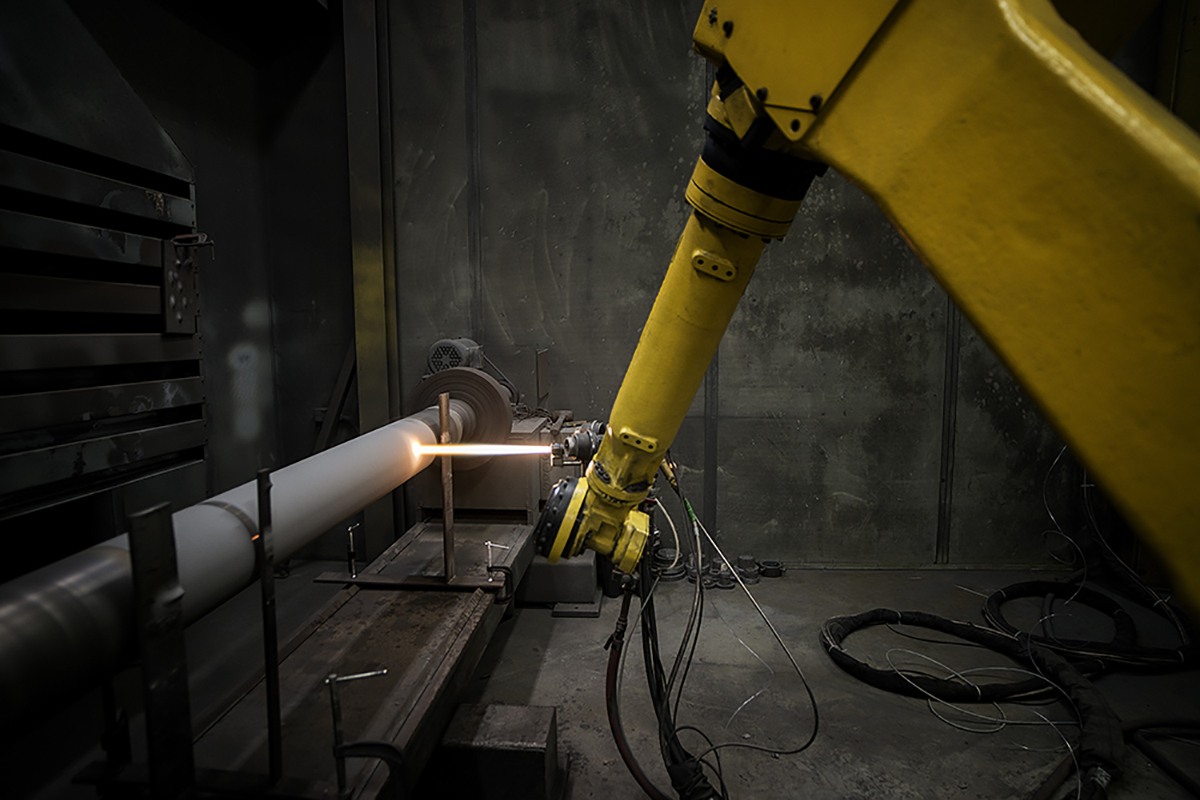

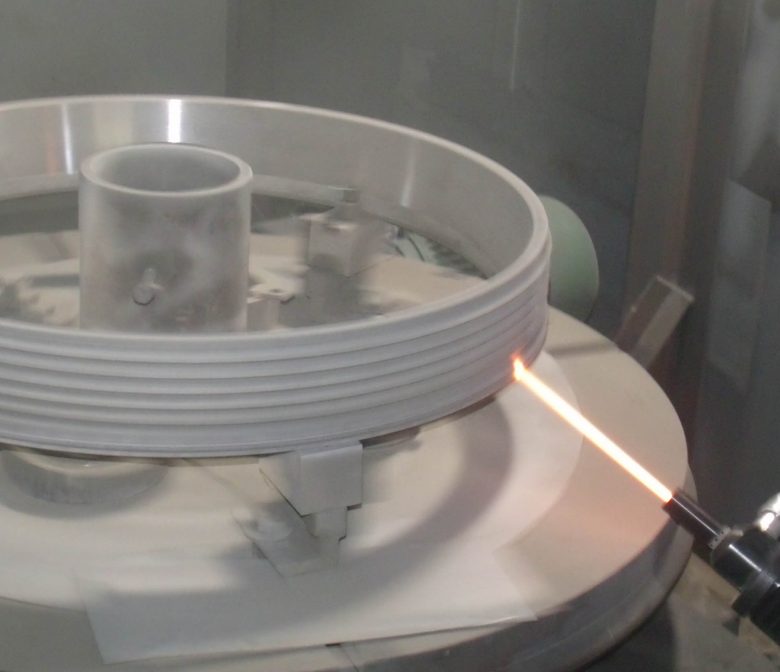

The Best High-Velocity Air Fuel (HVAF) Coating For Your Job

Superior Shot Peening & Coatings offers a special protective coating called High-Velocity Air Fuel (HVAF) thermal spray. This method uses oxygen as the fuel source to coat powder particles.

HVAF technology is suited for tungsten carbide coatings on pump housings and axles for the oil & gas industries. This special type of protecting coating is commonly used as a repair technology for the oil drilling and gas industries.