If you make a living by working with industrial machines, you know how important it is to have durable parts. The problem is that most of the parts you’re using — if they haven’t been treated — are not as strong as they could be.

Untreated metals are prone to rusting, breaking, chipping, fading, and jamming, and most industrial engineers and maintenance supervisors know not to trust them at face value.

If you want your equipment to last long and work well, you’re going to want to choose one of the two following protective coating treatments — fluoropolymer coating or powder coating — for your parts.

Fluoropolymer Coating: What Is It?

The first of these two treatments is fluoropolymer coating. Fluoropolymer is made of two parts: fluorine and polymer.

Polymer is a conjunction of many different molecules, including plastic, wool, silk, and rubber. Fluorine, meanwhile, is an electrically negative chemicals which will prevent the substance from sticking to other materials, thereby increasing lubrication.

- Fluoropolymer coatings are frequently used to insulate wiring, to reduce friction between car parts, and to protect metals from wear and tear.

Powder Coating: What Is It?

Powder coating is another great option if you want to keep your machinery up and running. Powder coating treatments are guaranteed to resist corrosion, chipping, scratching, and abrasions of all kinds.

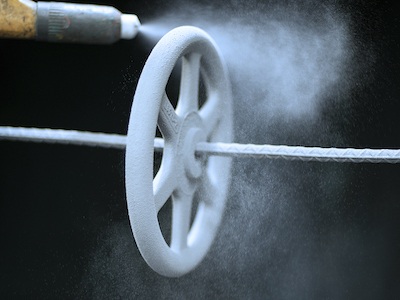

A good powder treatment consists of grounding up many different ingredients into a powder, including polymer resin, leveling agents and flow modifiers, and spraying them, statically charged, onto a metallic part.

The static electricity helps the powder stick to the metal. Then the part is moved into an oven where the powder is melted on to the piece, forming a strong bond across the surface area.

- Powder coating is used on BBQs, boats, signs, pipes, fittings, and engine parts of all kinds.

Contact Superior Shot Peening & Coatings

No matter your line of business — whether you are in the food industry, the automotive industry, or the oil and gas industry — the last thing you want to deal with is your equipment breaking down or not working properly.

Untreated metal parts can slow the work down, cause confusion and stress, and cost your company money. This is why your metal pieces need either a powder coating treatment or fluoropolymer treatment to optimize performance.

For more information, or to schedule our industry-leading coating services, contact us today. We would appreciate the opportunity to further discuss fluoropolymer coating vs. powder coating for your next job.