The integrity of industrial parts and components will begin to deteriorate after prolonged periods of use, which can cause undesired equipment failure.

A wide variety of industries such as manufacturing, chemical, energy, oil and gas, aviation, and aerospace, all require important maintenance services to ensure operational integrity. Investing in metal finishing solutions for the parts and components of your equipment can drastically extend the lifespan, durability, and usability.

What Are the Ideal Metal Finishing Solutions?

Consider the following three metal finishing solutions that extend equipment life through the treatment of parts and components.

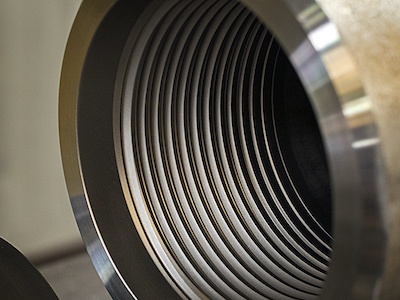

1. Shot Peening

Shot peening is an effective method to reduce the fatigue and stress on metal. Specially designed shot peening equipment is used to blast small projectiles onto the part or component, causing compression.

This metal finishing solution is primarily used for preventing equipment failure that is caused by corrosion and is helpful to increase the lifespan and durability of the part. Additionally, this solution provides benefits such as preventing galling, fretting, and cracking.

Some of the most common parts that can benefit from the shot peening treatment are gears, turbine blades, cams, and rock drills.

This method is also used for fixing any distortions, which smooths out the texture of the surface. The increased strength that is provided by the treatment allows light-weight parts to show high levels of resistance against fatigue and wear.

2. Powder Coating

Powder coating involves the application of a dry powder to a metal object. The use of powder over liquid coating will generally provide a thicker coating, which helps prevent common problems with liquid coating such as running or sagging.

The powder consists primarily of flow modifiers, leveling agents, pigments, curatives, and other materials. This powder is electrostatically applied to the metal and placed into an oven. The end result produces a chemical reaction that greatly increases the density of the metal.

Powder coating is an incredibly versatile method of strengthening metal that is used for a wide variety of industries. The finishes are typically customizable, and they’re designed to withstand extreme temperatures.

Overall, powder coating provides customers with an economical, long-lasting finish that is incredibly resistant to fading, scratching, chipping, and wearing. This process is also less impactful on the environment in comparison to similar finishing methods.

3. Abrasive Blasting

Abrasive blasting is a popular method that is also referred to as bead blasting or sandblasting. This method provides savings in the form of time, effort, and cost by streamlining the cleaning and finishing into one process.

High-pressure compressed air is utilized to project a variety of different substances such as sand, grit, shot, bead, organic materials, or silicon carbide onto the part. The application of these substances at high pressure simultaneously cleans, polishes, and finishes the part.

The material that is used is entirely dependent on the toughness of the surface. Tougher substances are used on hard surfaces, while softer substances are used on more delicate metal. The pressure of the air can also be adjusted to fit the needs and requirements of each specific part.

This method can be used to complete a variety of tasks such as cleaning boat hulls, car parts, oil rigs, and much more. Some of the most popular uses of abrasive blasting include:

- Removing sharp edges and burrs from manufacturing equipment.

- Removing old paint before a new coating is applied.

- Removing contaminants from a pipeline.

- Removing oxidation, rust, and mill scale

Which is the Best Method?

Each of these metal finishing solutions offers their own advantages, as well as differing levels of effectiveness that is dependent on the part or component being treated.

- Shot peening is generally used for strengthening oil and gas parts used in high-dollar equipment.

- Powder coating is generally used for aerospace and marine components, automobile parts, and drum hardware.

- Abrasive blasting is generally used for refurbishing buildings, cleaning structures, and is typically only used on metal.

Contact Superior Shot Peening & Coatings for Service

If you’re an engineer, maintenance supervisor, or project manager in a heavy-duty industry, contact Superior Shot Peening & Coatings to speak with an expert who can help you decide on the best metal finishing treatment for your parts.

We will help identify the best treatment of parts and components to ensure the longevity of your critical equipment so that your company remains operational in the field or at the job site.

To discuss metal finishing treatments with our team, contact us through our website, call 281-449-6559, or email info@superiorshotpeening.com to let us know your specific project needs.