A common question that companies have about shot peening their commercial or industrial parts is how the treatment affects the surface of a part.

You might be interested to know how much change to expect on the surface before you place the part back into service. Or, if you should be concerned about sub-surface issues.

Rest assured, the shot peening treatment is the ideal approach to enhance the surface finish of your part and address problems that are not easily visible. This is accomplished by creating a uniformly textured, finished surface that increases durability, longevity, and strength.

Shot Peening Addresses Fatigue Cracking and Residual Stress

One of the main purposes of shot peening is to prevent fatigue and residual stress. After being treated for this purpose, the surface finish is smoothed out, stress is evenly distributed, and the rate of fatigue cracking is brought to a halt.

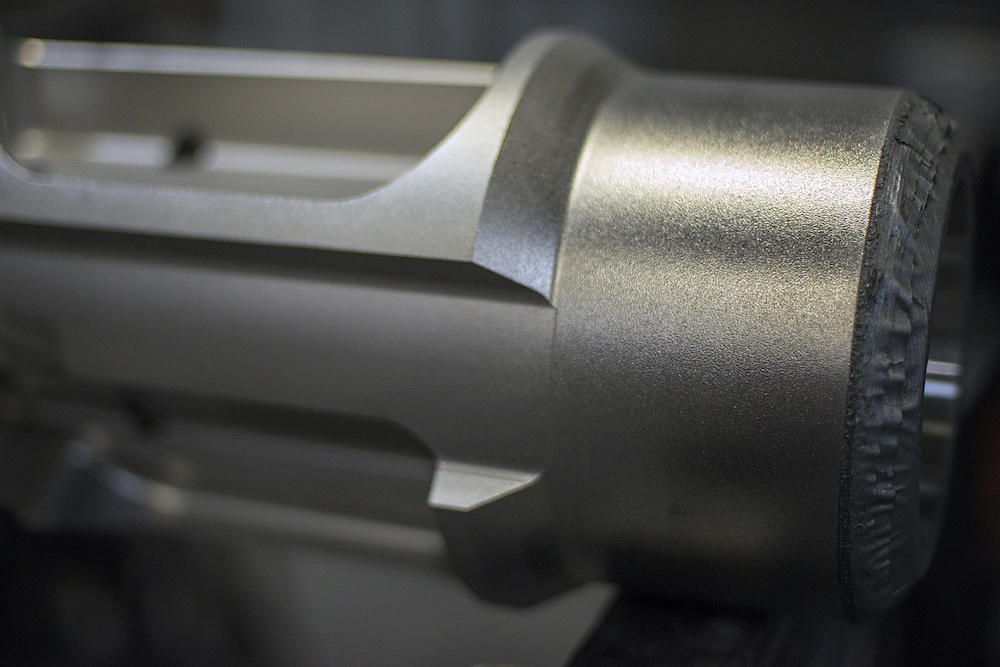

You can see signs of the treatment on the surface of the part by observing tiny dimples.

A shot-peened surface finish is covered in dimples that induce residual compressive stress on the surface. The compressive stress is critical to the shot peening process because it eliminates undesired residual stress.

Shot peening specifically addresses surface defects, notches, raised areas, and other changes to the composition of a part. You can see how each problem area is addressed to create a desired smooth, uniform surface.

The result is that old or damaged parts look like new and new parts are strengthened and smoothed out before being placed into use.

What About Problem Areas Below the Surface?

Another common question about the surface finish of a shot-peened part is whether we are overlooking the condition of the part below the surface.

The concern is that by only addressing raised areas on the surface, the shot peening treatment overlooks potential problem areas that are not as visible but could equally impact performance.

One of the best approaches to address this concern is search peening. This application exposes problem areas, such as hidden corrosion, and eliminates the issue by shot peening small problem areas.

Sub-surface corrosion is particularly common in areas directly surrounding metal fasteners, screws, and nails. This application is preferable to many other corrosion removal methods because it strengthens the metal while removing the hidden corrosion in problem areas.

The result is a strengthened and more durable part, both below the surface and visible on the surface finish.

SSPC Will Help Identify the Best Shot Peening Approach

Superior Shot Peening & Coatings (SSPC) has more than 25 years of experience shot peening industrial and commercial parts.

We will take the time to identify the best approach to treat your part after conducting a thorough examination of the condition of the part. We will be able to identify whether there are sub-surface issues that need to be addressed or if the part can be effectively treated on the surface.

The result of our process is a smooth, textured surface finish that will ensure your part is ready to be placed back into use in your equipment.

We perform the treatment either on-site at our facility in Texas or at your job site through the capabilities of our mobile-ready teams and equipment.

Contact us today to start your next shot peening job achieving the best surface finish for your part.