Find the Best Ball Valve Coating For Your Job

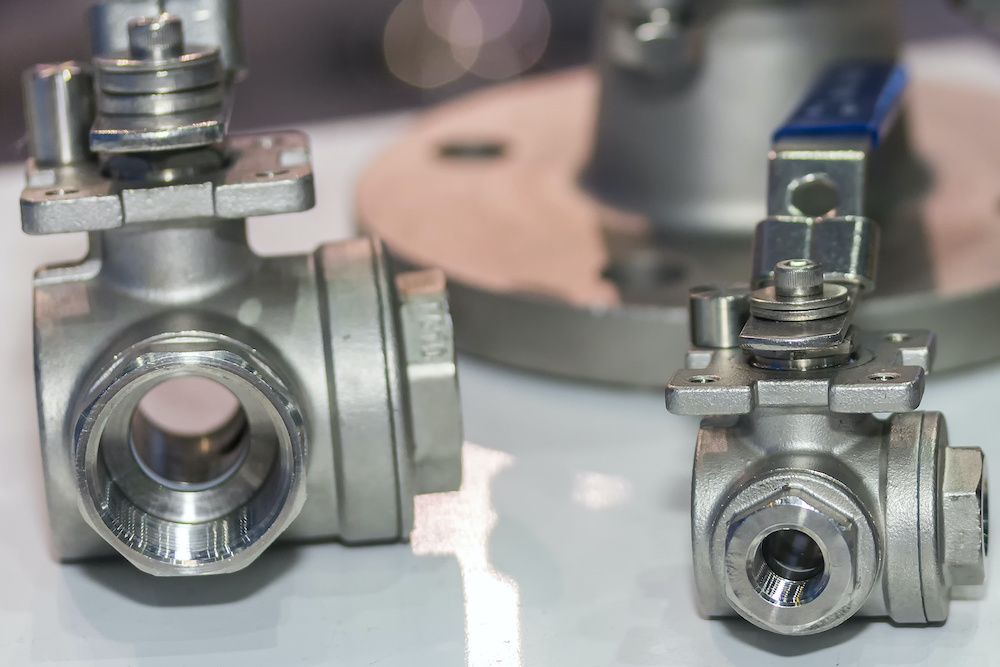

The integrity of metal seated ball valves is critical to support functionality in oil and gas, energy, manufacturing, aerospace, and similar industries. Ball valve coatings is a form of protective coating that ensures the durability and longevity of the part to withstand difficult conditions in harsh industrial settings.